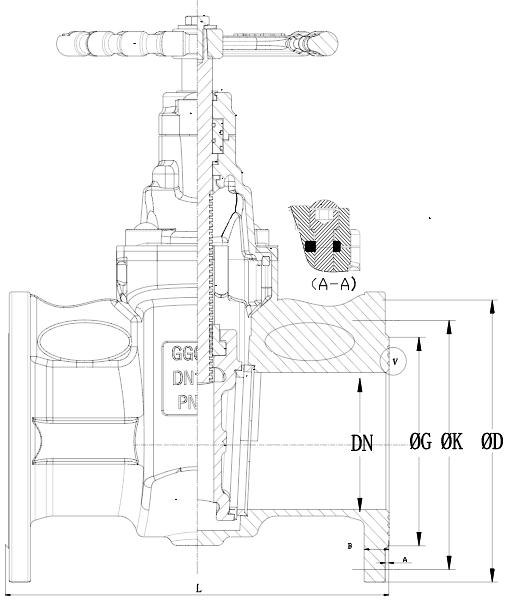

BNSV DIN 3352-F5 Metal Seat Gate Valve

Overview

The metal seat gate valve adopts copper ring inlay technology, and the valve disc adopts elastic design, which can achieve valve matching. It is widely used in tap water, sewage, construction and other fluid pipelines for maintenance, switching, and emptying.

Inverted sealed structure. The upper seal can be replaced under pressure

●Light torque. Able to achieve the same torque as the soft seal

●Full-diameter flat-bottom runner. The straight-through design of the full flow channel has low flow resistance, and the flat-bottomed valve seat is not easy to accumulate debris.

●Elastic disc. The gate adopts a reasonable design, which effectively solves the deformation of the valve body and processing errors.

●Stainless steel stem is rolled threaded. Stainless steel corrosion-resistant valve stem, threaded roll forming, smooth and wear-resistant, low operating torque and long service life.

●No leakage. Three-way "O" ring seal, compared with traditional packing, has higher sealing reliability, lower switch friction resistance, and more environmental protection and sanitation.

●Environmental protection and non-toxic, can be used in direct drinking water system. The inside and outside of the valve are sprayed with environmentally friendly and non-toxic epoxy resin. All parts in contact with water will not cause pollution. It can be used in drinking water, food and pharmaceutical industries.

●Two-way sealing. The flow direction of the medium is not restricted, and two-way sealing can be achieved.

No. | Parts | Material |

1 | Body | Ductile iron |

2 | Wedge | Ductile iron+brass |

3 | Bonnet | Ductile iron |

4 | Stem | Stainless steel,06Cr19Ni10(304) |

5 | Copper nuts | Brass |

6 | Hand wheel | Ductile iron |