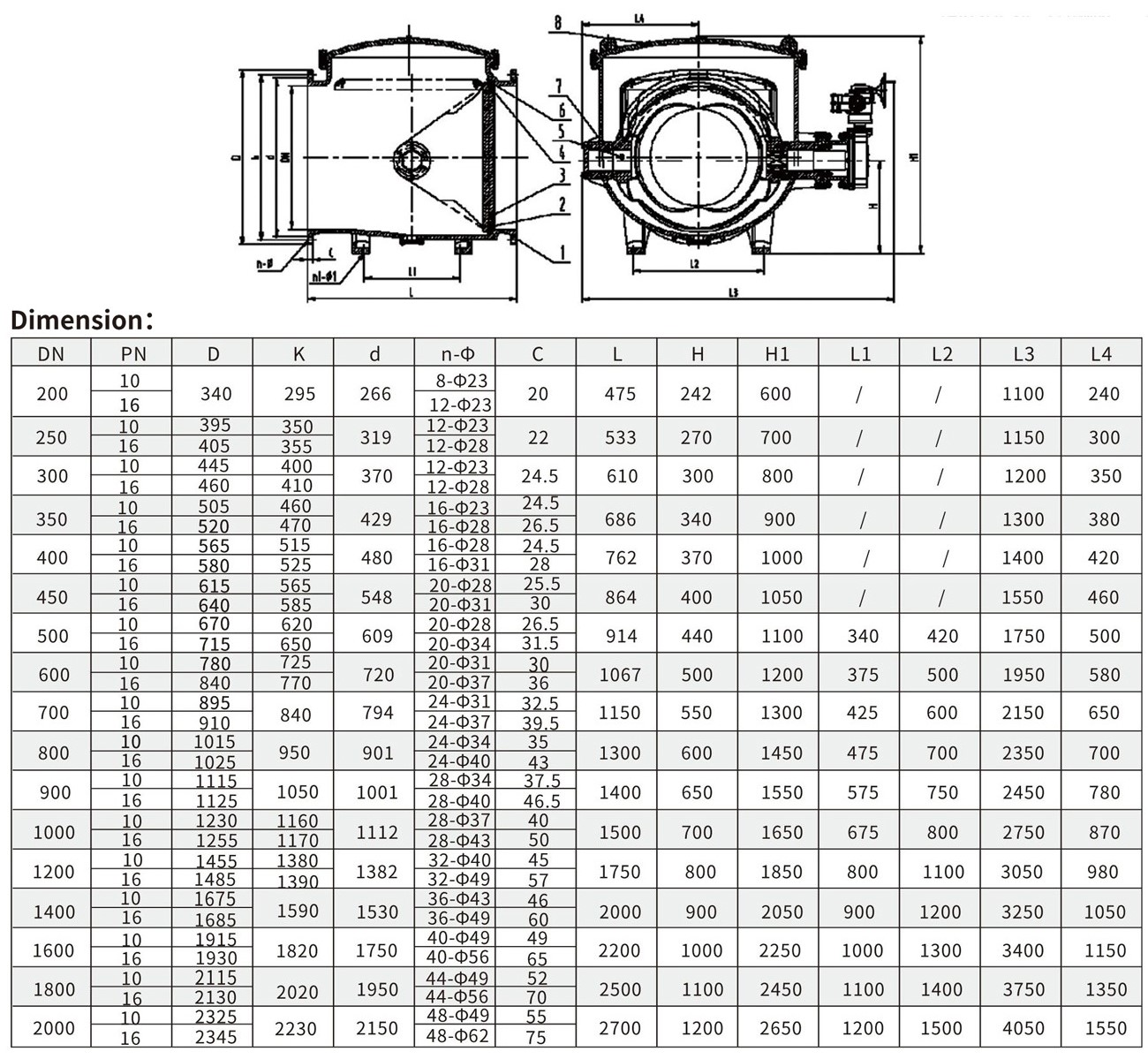

BNSV Eccentric hemisphere valve(top cover type)

Overview

The soft seal gate valve uses the compensation function of elastic deformation produced by the integral rubber coating of the gate to achieve good sealing effect, and overcomes the phenomenon of poor sealing, water leakage and rust of the traditional gate valve. It is widely used in tap water, sewage, building and other fluid pipes, and plays the role of maintenance, switch and evacuation.

The upper cover type eccentric hemisphere valve has all the advantages of the top mounted eccentric hemisphere valve, and also has the following advantages:

● The shaft seal is protected with flat bottom and no debris. The top mounted eccentric hemispherical valve is vertical shaft structure with a deep groove similar to hard seal gate valve at the bottom, which is easy to accumulate solid waste and the shaft seal is easy to be damaged. The upper cover type eccentric hemispherical valve is of horizontal shaft structure, and the ball crown is located at the upper part of the valve body when the ball crown is opened, so the bottom is flat, and the debris in the water can be carried away by the water flow smoothly, without winding and accumulation.

● The horizontal valve shaft does not shift. The traditional vertical shaft structure gravity downward, once displaced, the seal will be affected, resulting in leakage. The eccentric hemispherical valve with upper cover is of horizontal shaft structure, and the valve core is supported by two fulcrums, which will not shift.

● Online maintenance is more convenient and effective. During on-line maintenance of the top mounted eccentric hemisphere valve, it is necessary to take down the worm gear head, remove the valve cover, and take out the valve core before it can be repaired. There are two disadvantages: one is that the workload is heavy, and the maintenance of large diameter valve requires crane and other lifting equipment; the other is that when the valve core is taken out and re installed into the valve, the relative position of the ball crown and valve seat cannot be ensured, resulting in the phenomenon of loose sealing. In the on-line maintenance of the eccentric hemispherical valve, it is only necessary to open the valve cover, and the workload is very small. Moreover, when replacing the sealing ring and the ball crown, the valve core does not need to be moved, and the sealing effect after replacement is very reliable.

No. | Parts | Material |

1 | Body | Ductile iron QT450-10、WCB |

2 | Spherical cap | Stainless steel 20Cr13 |

3 | disc | Ductile iron QT450-10、WCB |

4 | Rubber seat | EPDM or NBR |

5 | Driving shaft、driven shaft | Stainless steel 20Cr13 |

6 | seat | Stainless steel 304 |

7 | Upper and lower shaft sleeves | Copper alloy composite shaft sleeve |

8 | fastener | A2-70 and galvanized carbon steel |

9 | Upper cover | Ductile iron QT450-10、WCB |

10 | O ring | EPDM or NBR |